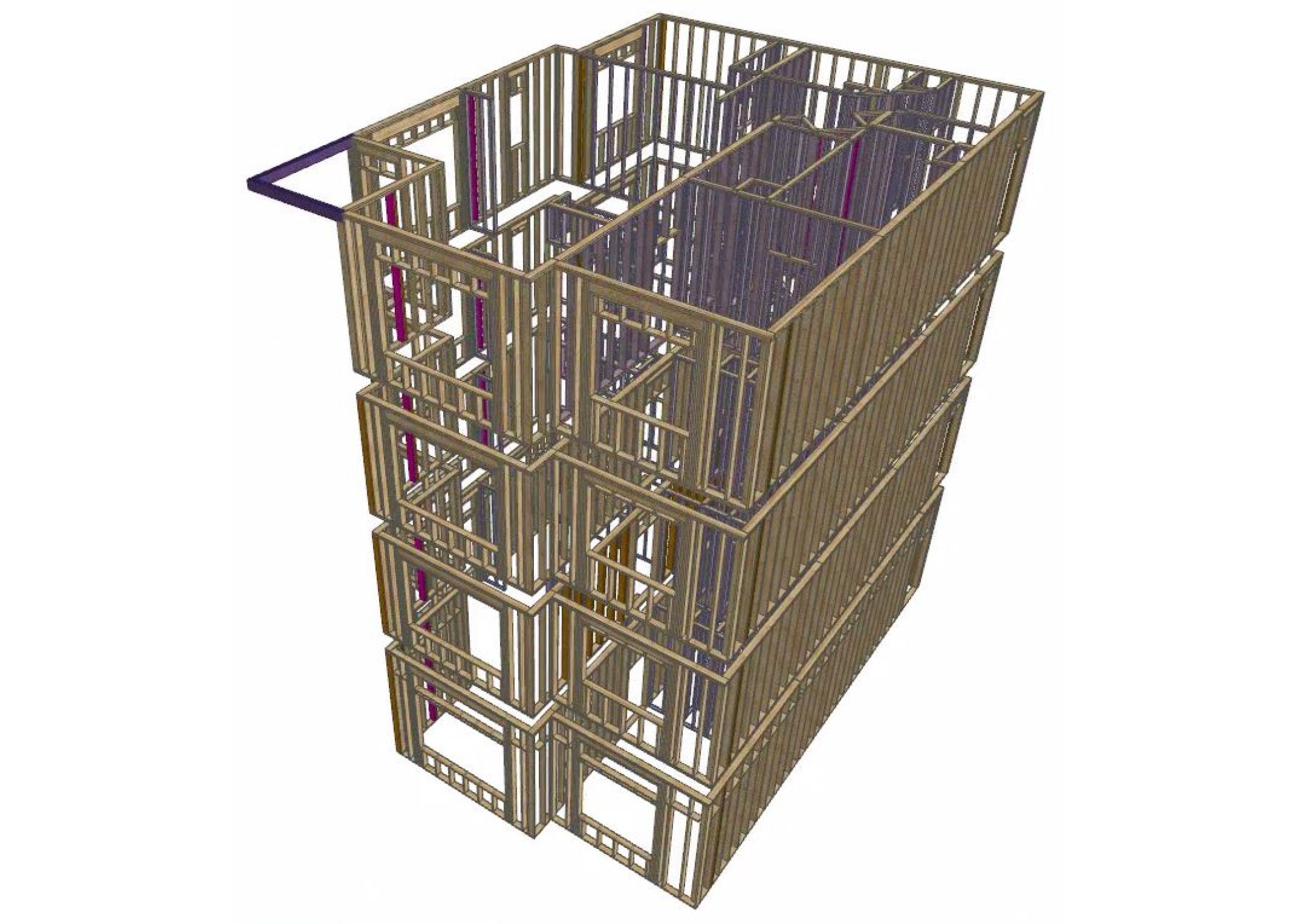

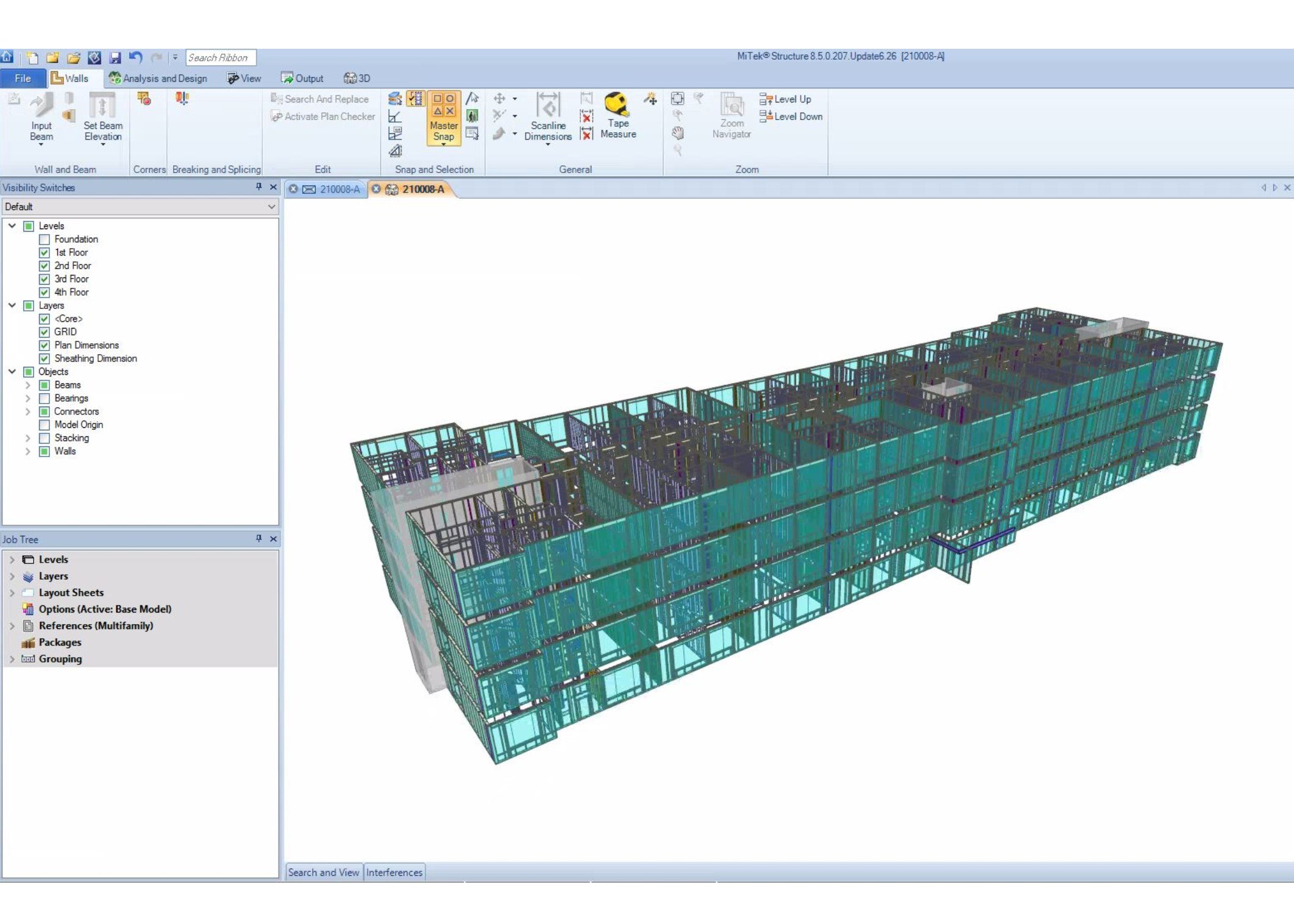

Our manufacturing facility is driven by 3D computer modeling using MiTek Sapphire. This comprehensive structural model calculates everything from each individual stud to the loads through the trusses and wall panels of the building.

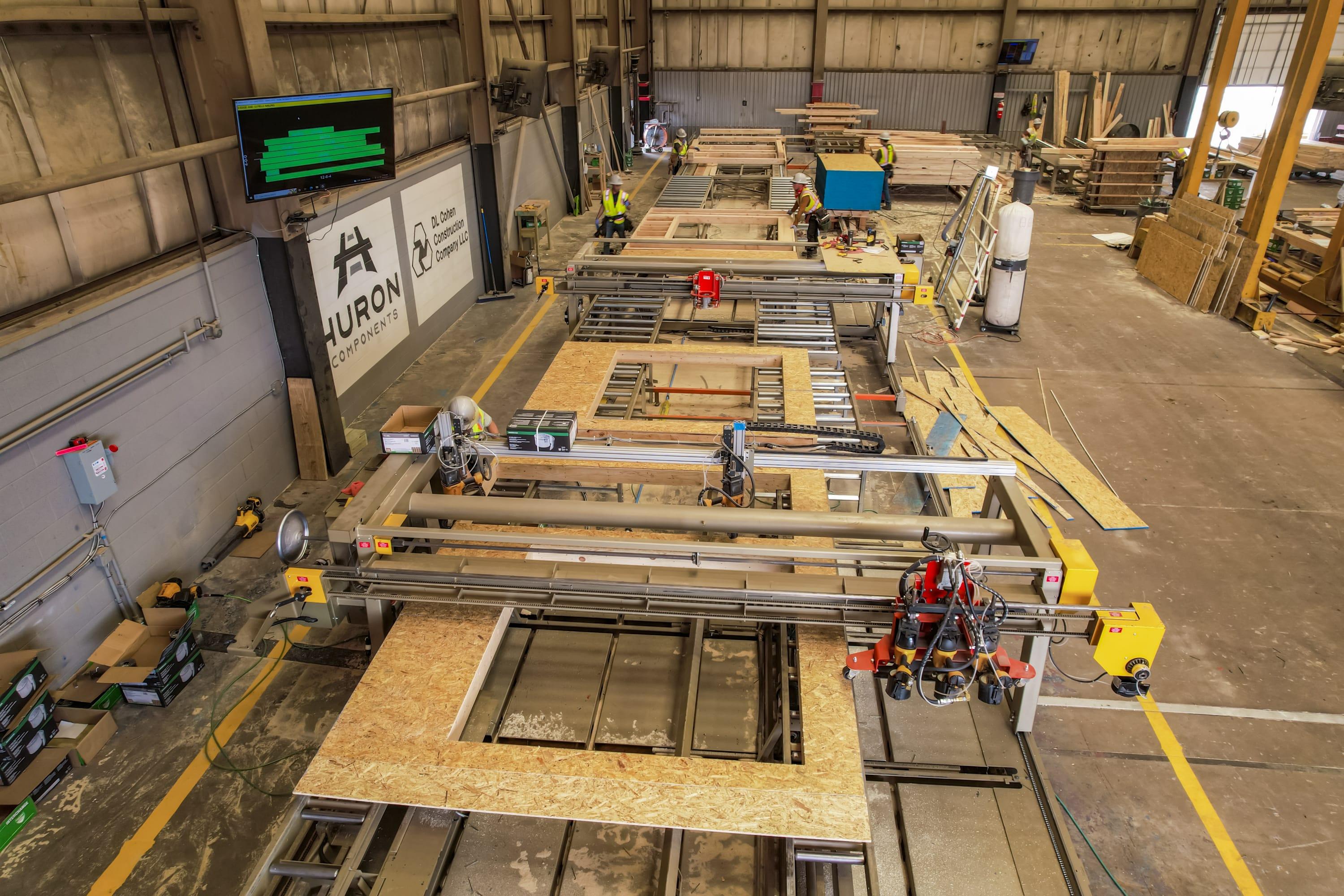

Offsite componentization of wall panels allows for higher quality product and faster assembly at the project site. The off-site process also allows for an increase in efficiency to reduce material waste 15 - 20%, decrease schedule and decrease the field labor required to assemble yielding a better value proposition for all parties.

Our Truss division designs and provides the floor and roof creating a fully integrated structure to ensure proper loading throughout the project. In-house floor truss production allows Huron to further reduce material waste from wall panels while also giving better control of truss collation and delivery for our field operations.